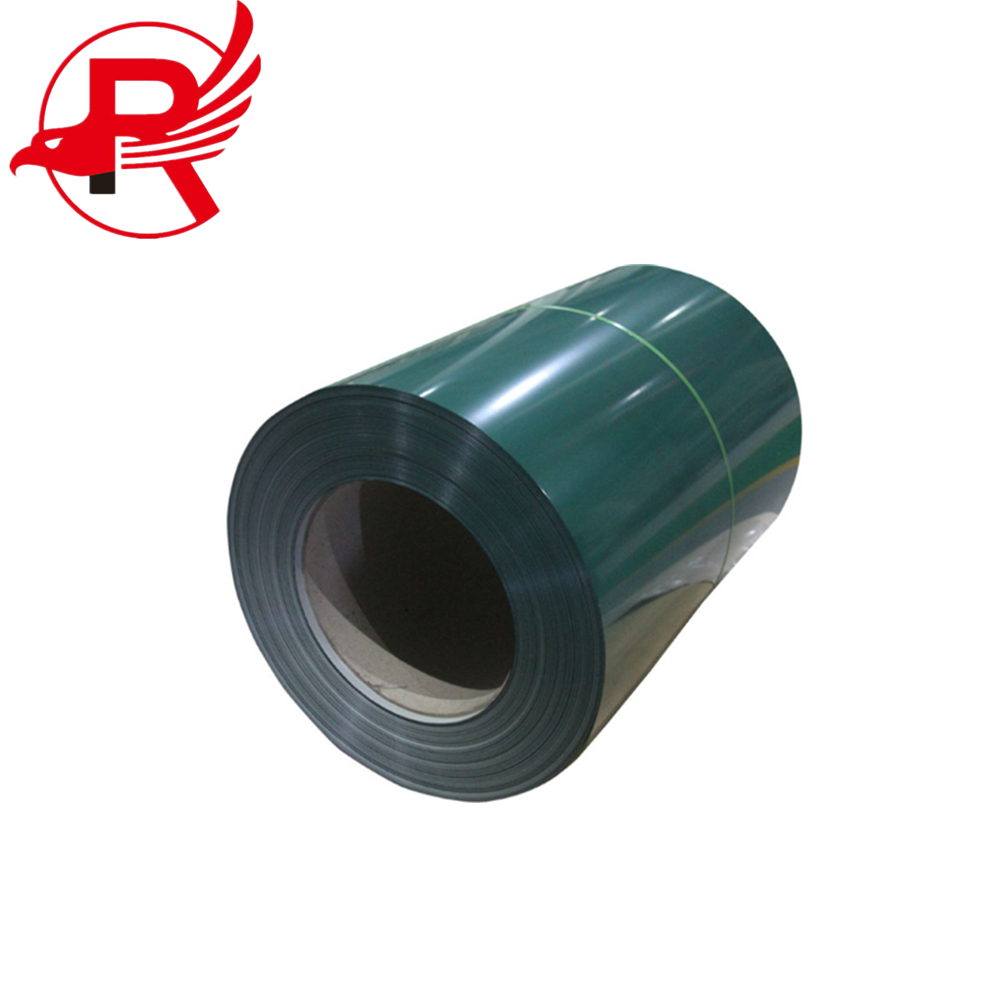

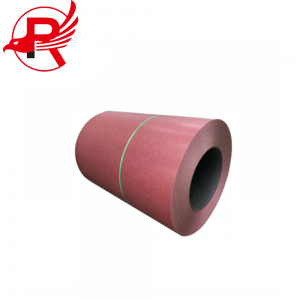

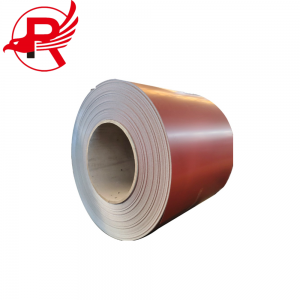

Ahịa ọkụ DX51D+z PPGI PPGL Ígwè e ji agba kpuchie agba nke e sere agba n'elu ya nke e ji ígwè a na-akpọ "Cold Rolled Steel Coil" mee.

| Aha Ngwaahịa | Ral 9002/9006 ppgI a na-ese gi ígwè eriri igweeriri ppgi |

| ihe | Q195 Q235 Q345 |

| SGCC SGCH SGC340 SGC400 SGC440 SGC490 SGC570 | |

| DX51D DX52D DX53D DX54D DX55D DX56D DX57D | |

| Ọkpụrụkpụ | 0.125mm ruo 4.0mm |

| Obosara | 600mm ruo 1500mm |

| Mkpuchi Zinc | 40g/m2 ruo 275g/m2 |

| Ihe ndị dị n'okpuru ala | Ala a kpụrụ akpụ nke oyi / Ala a kpụrụ akpụ nke ọkụ |

| Agba | Usoro Agba Ral ma ọ bụ dịka ihe nlereanya agba nke onye zụrụ ya si dị |

| Ọgwụgwọ elu | A kpụchara akpụcha ma tee mmanụ, yana ant-ifingers |

| Ike siri ike | Dị nro, ọkara siri ike na ịdị mma siri ike |

| Ibu eriri igwe | Tọn atọ ruo tọn asatọ |

| NJ eriri igwe | 508mm ma ọ bụ 610mm |

1)PPGIA na-ejikarị ya eme ihe n'ọtụtụ ebe a na-arụ ọrụ n'ụlọ ọrụ buru ibu, ụlọ nkwakọba ihe, ụlọ ọrụ, ụlọ elu, ụlọ nhicha ikuku, ebe a na-echekwa oyi, na ụlọ ahịa.

2. Otu EzePPGI, nke nwere oke kachasị elu na ikike ọkọnọ siri ike ka ejiri mee ihe n'ọtụtụ ebe na nhazi ígwè na owuwu.

Ihe ndetu:

1. Nnwale efu, nkwa mma 100% mgbe ire ere gasịrị, Kwado usoro ịkwụ ụgwọ ọ bụla;

2. Nkọwapụta ndị ọzọ niile gbasara PPGI dị dịka gị si dị

ihe achọrọ (OEM na ODM)! Ọnụ ahịa ụlọ ọrụ ị ga-enweta site na ROYAL GROUP.

Usoro mmepụta nke eriri ígwè galvanized e sere agba nke ọma gụnyere ọtụtụ nzọụkwụ dị mkpa iji hụ na ngwaahịa ikpeazụ dị mma ma rụọ ọrụ nke ọma. Nke a bụ nkọwa nke usoro mmepụta a na-ahụkarị:

Nhọrọ Ihe: Usoro a na-amalite site na nhọrọ nke eriri ígwè galvanized dị elu. A na-ejikarị ígwè a na-akpọ "coils" eme eriri ndị a nke e ji akwa zinc kpuchie iji nye ike iguzogide nchara.

Nhicha Elu: A na-ehicha eriri ígwè ndị a nke e ji galvanized mee nke ọma iji wepụ mmanụ, unyi, ma ọ bụ ihe ndị ọzọ na-emerụ ahụ n'elu ya. Nke a dị mkpa iji hụ na e tinyere ihe mkpuchi agba ahụ n'ime ya nke ọma.

Ọgwụgwọ Elu: Mgbe e sachara ya, eriri ígwè ahụ nwere ike ịgafe usoro ọgwụgwọ elu dịka mkpuchi kemịkalụ ma ọ bụ chromate passivation iji mee ka agba ahụ na-arapara nke ọma ma melite iguzogide nchara.

Ngwa praịma: A na-etinye ihe mkpuchi praịmarị n'elu ígwè e kpochara ma gwọọ. Ihe mkpuchi praịmarị ahụ na-enyere aka ịkwalite nrapado nke ihe mkpuchi elu ahụ ma na-enye nchebe nchara ọzọ.

Ngwa Topcoat: A na-ete ihe mkpuchi ígwè e ji agba ígwè rụọ nke e sere n'elu ya na agba e ji agba pụrụ iche kpuchie ya. E mere agba a ka ọ na-enye agba, ogologo oge, na nchebe ọzọ megide ihe ndị dị ka radieshon UV na mmiri.

Ọgwụgwọ: A na-agafe eriri ígwè e ji ihe kpuchie ya site na oven na-agwọ ọrịa ebe a na-etinye agba ahụ n'elu ya. Usoro a na-eme ka agba ahụ na-arapara nke ọma ma na-ejikọta ya na ibe ya, na-eme ka ọ dịgide ogologo oge.

Jụụ na Nnyocha: Mgbe ọ gbasasịrị, a na-ajụ oyi ma lelee eriri ígwè e ji galvanized mee ka ha dị mma. A na-achọpụta ma dozie nsogbu ma ọ bụ ntụpọ ọ bụla tupu e kwadebe eriri ndị ahụ maka mbupu.

Ịkpụcha na Nkwakọ ngwaahịa: Enwere ike ịkpụcha eriri ndị emechara iji ruo obosara achọrọ, wee kechie ha ma kwadebe ha maka ikesa ha nye ndị ahịa.

Nkwakọ ngwaahịa na-abụkarị site na ngwugwu ígwè na ngwugwu mmiri na-adịghị agbaze, eriri ígwè na-ejikọ, siri ike nke ukwuu.

Ọ bụrụ na ị nwere ihe pụrụ iche achọrọ, ị nwere ike iji ihe mkpuchi nchara na-egbochi nchara, ma mara mma karịa.

Njem:Nnyefe Ngwa Ngwa (Nnyefe Ihe Nlereanya), Ikuku, Ụgbọ okporo ígwè, Ala, Mbupu Oké Osimiri (FCL ma ọ bụ LCL ma ọ bụ Nnukwu)

Q: Ị bụ onye nrụpụta?

A: Ee, anyị bụ ndị nrụpụta ihe. Anyị nwere ụlọ ọrụ mmepụta ihe nke anyị dị na Tianjin City, China.

Q: Enwere m ike ịnweta iwu nnwale naanị tọn ole na ole?

A: N'ezie. Anyị nwere ike ibuga ibu ahụ maka gị site na ọrụ LCL. (Ọ dịghị ibu ibu dị obere)

Q: Ọ bụrụ na sample bụ n'efu?

A: N'efu ihe nlele, mana onye zụrụ ya na-akwụ ụgwọ maka ibu ahụ.

Q: Ị bụ onye na-eweta ọlaedo ma na-eme nkwa azụmaahịa?

A: Anyị na-enye ndị na-ere ahịa ọlaedo afọ asaa ma na-anabata nkwa azụmaahịa.