-

DX54D RAL Ọcha PPGI Mpịakọta Agba Ejiri Agba Mee Ka A Na-ese Ya Agba Ejiri Agba Mee Ka A Na-ese Ya Agba

PPGIA na-eji mpempe ígwè galvanized na-ekpo ọkụ na efere zinc aluminom a mịrị amị mee ya dị ka ihe ndabere. Mgbe a gwọchara ya tupu oge eruo, a ga-ekpuchi ha oyi akwa ma ọ bụ akwa mkpuchi organic, wee sie ya ma sie ya ruo mgbe ọ ga-emepụta ya. A na-ejikwa ọtụtụ agba dị iche iche nke efere ígwè agba mkpuchi organic kpuchie ha, nke a na-akpọ "coil agba agba". A na-ejikarị ha eme ihe ma n'ime ma n'èzí ihe owuwu ụlọ, ngwa ụlọ na ubi ndị ọzọ.

-

China Ral 9002 agba PPGI nke e ji ígwè kpuchie agba kpuchie

PPGIA na-eji mpempe ígwè galvanized na-ekpo ọkụ na efere zinc aluminom a mịrị amị mee ya dị ka ihe ndabere. Mgbe a gwọchara ya tupu oge eruo, a ga-ekpuchi ha oyi akwa ma ọ bụ akwa mkpuchi organic, wee sie ya ma sie ya ruo mgbe ọ ga-emepụta ya. A na-ejikwa ọtụtụ agba dị iche iche nke efere ígwè agba mkpuchi organic kpuchie ha, nke a na-akpọ "coil agba agba". A na-ejikarị ha eme ihe ma n'ime ma n'èzí ihe owuwu ụlọ, ngwa ụlọ na ubi ndị ọzọ.

Na ihe karịrịAfọ iriahụmịhe mbupụ ígwè ruo ihe karịrịMba 100, anyị enwetala aha ọma na ọtụtụ ndị ahịa nkịtị.

Anyị ga-akwado gị nke ọma n'oge usoro a niile site na ihe ọmụma ọkachamara anyị na ngwaahịa dị elu.

Ihe nlele ngwaahịa bụ n'efu ma dị!Nabata ajụjụ gị!

-

Galvanlume PPGL RAL Agba SGCC AZ275 Ejiri ígwè Galvanized agba agba maka mpempe akwụkwọ elu ụlọ

PPGLnke ahụ bụ efere mkpuchi Aluminom-zinc (AZ150, G345A, PVDF) dabara nke ọma maka ụlọ ma ọ bụ ụlọ ọrụ ndị ọzọ dị na gburugburu ebe obibi dị oke njọ, iguzogide nchara na iguzogide ihu igwe, ígwè a nwekwara ike ikwe nkwa ndụ ọrụ ihe karịrị afọ 20. Na mgbakwunye, ejirila efere ígwè dị ike nke ukwuu na mba ofesi, yana ezigbo akụ na ụba, kamakwa usoro mmepe na China.

-

Dx51d Ral 9002/9006 PPGL Ejiri agba ígwè GI nke e sere agba nke ọma

PPGIA na-eji mpempe ígwè galvanized na-ekpo ọkụ na efere zinc aluminom a mịrị amị mee ya dị ka ihe ndabere. Mgbe a gwọchara ya tupu oge eruo, a ga-ekpuchi ha oyi akwa ma ọ bụ akwa mkpuchi organic, wee sie ya ma sie ya ruo mgbe ọ ga-emepụta ya. A na-ejikwa ọtụtụ agba dị iche iche nke efere ígwè agba mkpuchi organic kpuchie ha, nke a na-akpọ "coil agba agba". A na-ejikarị ha eme ihe ma n'ime ma n'èzí ihe owuwu ụlọ, ngwa ụlọ na ubi ndị ọzọ.

-

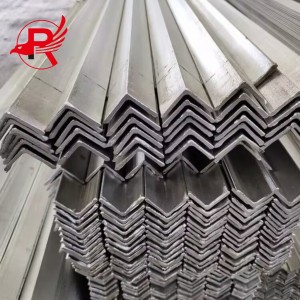

Ọnụahịa ụlọ ọrụ mmepụta ihe 40x40x4mm Q235B ígwè a na-akpụ akpụ nke e ji ígwè rụọ maka nhazi L

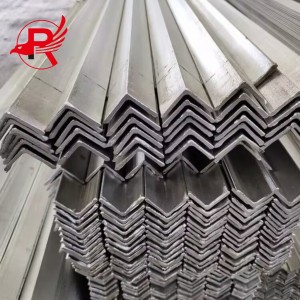

Mgbe eji yaígwè angle galvanized,Ihe ndị a kwesịrị ịma. Nke mbụ, hụ na ejikọtara ya nke ọma na nkwado ma ọ bụ ihe owuwu ndị ọzọ iji zere ịma jijiji ma ọ bụ ịda; Nke abụọ, ọ dị mkpa ijide n'aka na akwa zinc dị n'elu ya adịghị emebi emebi iji zere mmebi igwe ma ọ bụ nchara kemịkalụ; N'ikpeazụ, ọ dị mkpa ịwụnye ma dobe ya dịka ihe achọrọ si dị iji hụ na nchekwa ya na ịdịte aka ya.

-

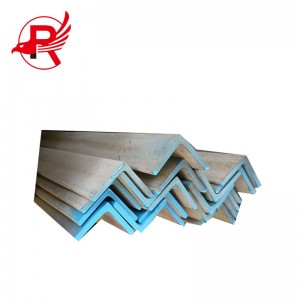

Angle Galvanized Angle Q235B3 Na-ekpo ọkụ # 5 # 8 # 20 # Ọrụ ígwè Triangle Galvanized maka Shelves ịgbado ọkụ

Nkọwapụta na ụdị nke gígwè n'akụkụ alvanizedenwere ike ịhazi ya dịka mkpa ụfọdụ si dị. N'ozuzu, nkọwapụta nke ígwè angle galvanized gụnyere paramita dịka ogologo, obosara na ọkpụrụkpụ, a na-ekewakwa ụdị ya dịka ihe eji arụ ọrụ na ojiji ha si dị.

-

Nkuku ígwè ASTM A36 Carbon nhata nkuku ígwè galvanized ígwè L Ọdịdị dị nro ígwè nkuku ogwe

Ígwè ígwè e ji ígwè rụọbụ ígwè a na-ejikarị arụ ọrụ, nke a na-ejikarị arụ ọrụ n'ihe owuwu, àkwà mmiri, okporo ụzọ na ubi ndị ọzọ. Uru ya gụnyere ike dị elu, iguzogide nchara, iguzogide ọkụ na ihe ndị ọzọ.

-

SS400 Steel Galvanized Angle Iron Dị Mfe Nhata Angle

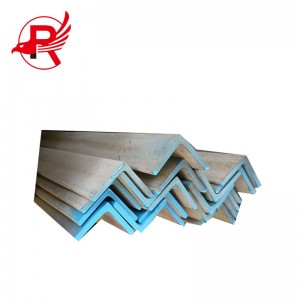

Ígwè ígwè e ji ígwè rụọA na-ejikarị ya eme ihe n'ụlọ elu ike, ụlọ elu nkwukọrịta, ihe mgbidi ákwà mgbochi, owuwu shelf, ụgbọ okporo ígwè, nchekwa okporo ụzọ, ogwe ọkụ okporo ụzọ, ihe ndị dị n'ime mmiri, ihe ndị mejupụtara ígwè ụlọ, ihe ndị dị n'okpuru ebe a na-arụ ọrụ, ụlọ ọrụ ọkụ, wdg.

-

Ogwe ígwè ígwè nke a na-akpụ akpụ nke Q345

Okpomọkụ dị na galvanized oyi akwaígwè n'akụkụ galvanizedỌ bụ otu ọkpụrụkpụ, ruo 30-50um, ma nwee ntụkwasị obi dị mma. A na-ejikọta akwa galvanized na ígwè ahụ ma ghọọ akụkụ nke elu ígwè ahụ, yabụ na mkpuchi siri ike nke ígwè galvanized na-ekpo ọkụ na-adịgide adịgide ga-adịkwu mma. Ihe e ji mee ígwè galvanized na-ekpo ọkụ bụ ígwè Angle, yabụ nhazi ya bụ otu ihe ahụ dị ka ígwè Angle.

-

Q235 Q345 Q355 N'ogbe, ígwè e ji akụkụ nhata kpọọ ọkụ, 201 304 316 Ss, ígwè e ji akụkụ nhata rụọ, ígwè e ji akụkụ a rụnyere n'akụkụ nke ...

A na-ekewa ígwè akụkụ Galvanized n'ime ígwè akụkụ Galvanized n'akụkụ ọkụ na ígwè akụkụ Galvanized n'akụkụ oyi. A na-akpọkwa ígwè akụkụ Galvanized n'akụkụ ọkụ na-amị amị nke a ...

-

Ogwe Ogwe Angle Slotted 100x100x6 SS41B nke e ji ígwè rụọ maka imewe ogige

A na-ekewa ígwè akụkụ Galvanized n'ime ígwè akụkụ galvanized na-ekpo ọkụ na ígwè akụkụ galvanized n'akụkụ oyi. A na-akpọkwa ígwè akụkụ galvanized na-ekpo ọkụ na-ekpo ọkụ na ígwè akụkụ galvanized ma ọ bụ ígwè akụkụ galvanized na-ekpo ọkụ. Mkpuchi galvanized na-ekpo ọkụ na-eme ka njikọ zuru oke dị n'etiti ntụ zinc na ígwè ahụ site na ụkpụrụ electrochemical, ma na-emepụta ọdịiche nwere ike ịnwe electrode maka mgbochi corrosion.

-

Ụlọ ọrụ mmepụta ihe na China nke a na-akpọ Hot Rolled dị nro nke a na-akpọ ST37 Steel Angle Bar maka owuwu

A na-ekewa ígwè e ji ígwè rụọ n'akụkụ nke e ji ígwè rụọ n'ime mmiri ọkụ.ígwè nkuku galvanizedna ígwè angle galvanized nke a na-etinye n'ime mmiri oyi. A na-akpọkwa ígwè angle galvanized nke a na-etinye n'ime mmiri ọkụ ma ọ bụ ígwè angle galvanized nke a na-etinye n'ime mmiri ọkụ. Mkpuchi galvanized nke a na-etinye n'ime mmiri oyi na-eme ka njikọ zuru oke dị n'etiti ntụ zinc na ígwè ahụ site na ụkpụrụ electrochemical, ma na-emepụta ọdịiche nwere ike ịnwe electrode maka mgbochi corrosion.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur