API 5L Gr. B Carbon Line Pipe Enweghị Nsogbu

| Ọkwa | API 5L Klas B, X42, X52, X56, X60, X65, X70, X80 |

| Ọkwa nkọwapụta | PSL1, PSL2 |

| Oke Dayameta Mpụta | 1/2” ruo 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16”, 18”, 20”, 24” ruo 40”. |

| Usoro Ọkpụrụkpụ | SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, ruo SCH 160 |

| Ụdị Mmepụta | Enweghị Ntụpọ (A na-akpọgharị ọkụ na oyi), ERW (A na-ejikọ ike eletriki), SAW (A na-ejikọ aka n'ime mmiri) na LSAW, DSAW, SSAW, HSAW |

| Ụdị njedebe | Ọkụkọ ndị a kpụchara akpụcha, Ọkụkọ ndị a kpụchara akpụcha |

| Ogologo Ogologo | SRL (Ogologo Otu Enweghị Nhọrọ), DRL (Ogologo Ugboro Abụọ), 20 FT (mita 6), 40 FT (mita 12) ma ọ bụ, ahaziri ya |

| Okpu Nchedo | plastik ma ọ bụ ígwè |

| Ọgwụgwọ Elu | Ihe osise sitere n'okike, nke e ji agba ọbara ọbara mee, nke e ji oji mee, FBE, 3PE (3LPE), 3PP, CWC (Mkpuchi arọ simenti) CRA kpuchie ma ọ bụ kpuchie ya |

Paịpụ API 5L na-ezo aka na paịpụ ígwè carbon nke e ji eme ihe na sistemụ nnyefe mmanụ na gas. A na-ejikwa ya ebuga mmiri ndị ọzọ dịka uzuoku, mmiri, na apịtị.

Nkọwapụta API 5L na-ekpuchi ma ụdị mmepụta a na-agbakọta na nke na-enweghị ntụpọ.

Ụdị ndị e ji agbakọta: ERW, SAW, DSAW, LSAW, SSAW, HSAW Pipe

Ụdị ọkpọkọ API 5L a na-ahụkarị bụ ndị a:

ERW: Ịgbado ọkụ eletrik, nke a na-ejikarị eme ihe maka dayameta paịpụ na-erughị sentimita iri abụọ na anọ.

DSAW/SAW: Ịgbado arc nke nwere akụkụ abụọ n'ime mmiri/ịgbado arc nke e tinyere n'ime mmiri, ụzọ ọzọ e si agbado arc nke a na-eji eme paịpụ ndị buru ibu karịa nke ERW.

LSAW: Njikọta arc nke dị n'okpuru mmiri ogologo, nke a na-eji maka dayameta paịpụ ruo sentimita iri anọ na asatọ. A makwaara ya dị ka usoro mmepụta JCOE.

SSAW/HSAW: Ịgbado arc gbara okirikiri/ịgbado arc gbara okirikiri, nke a na-eji maka dayameta paịpụ ruo sentimita 100.

Ụdị Paịpụ Na-enweghị Ntụpọ: Paịpụ a na-akpọ ọkụ nke na-enweghị ntụpọ

A na-ejikarị paịpụ ígwè na-enweghị ntụpọ eme ihe maka obere paịpụ dayameta (ọ na-adịkarịghị sentimita iri abụọ na anọ).

(Ọkacha mma ka ọ bụrụ paịpụ ígwè na-enweghị ntụpọ karịa paịpụ a gbanyere agba maka dayameta na-erughị 150 mm (inchi 6)).

Anyị na-arụkwa nnukwu paịpụ dayameta na-enweghị ntụpọ. Site n'iji usoro a na-akpọ "hot-rolled", enwere ike ịmepụta paịpụ na-enweghị ntụpọ nke nwere dayameta kachasị nke sentimita iri abụọ (508 mm). Ọ bụrụ na ịchọrọ ka paịpụ na-enweghị ntụpọ nke nwere dayameta karịrị sentimita iri abụọ (20"), anyị nwere ike imepụta paịpụ na-enweghị ntụpọ site na usoro a na-akpọ "hot-expand" nke nwere dayameta ruo sentimita iri anọ (1016 mm).

API 5L gụnyere akara dịka Klas B, X42, X46, X52, X56, X60, X65, X70 na X80.

A na-enweta API 5L Steel Pipe n'ọtụtụ ọkwa ígwè dịka Grade B, X42, X46, X52, X56, X60, X65, X70 na X80. Ka ọkwa ígwè ahụ dị elu, otú ahụ ka njikwa nhata carbon na-esi ike ma na-eme ka ikike ike igwe dịkwuo elu.

Ọzọkwa, ihe mejupụtara kemịkalụ nke ọkpọkọ API 5L nke a gbanyere agbakọta na nke na-enweghị ntụpọ nwere otu ọkwa ígwè nwere ihe dị iche, nke ọkpọkọ ndị a gbanyere agbakọta nwere ihe dị elu na obere ọdịnaya nke carbon na sọlfọ.

Ngwakọta kemịkalụ maka paịpụ PSL 1 nwere t ≤ 0.984” | |||||||

| Ọkwa ígwè | Nkebi oke, pasentị dabere na nyocha okpomọkụ na ngwaahịa a, g | ||||||

| C | Mn | P | S | V | Nb | Ti | |

| kacha b | kacha b | kachasị | kachasị | kachasị | kachasị | kachasị | |

| Pipe Enweghị Nsogbu | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.28 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.28 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.28 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.28 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| Pipe a na-agbakọta | |||||||

| A | 0.22 | 0.9 | 0.03 | 0.03 | – | – | – |

| B | 0.26 | 1.2 | 0.03 | 0.03 | c,d | c,d | d |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | d | d | d |

| X46 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X56 | 0.26 | 1.4 | 0.03 | 0.03 | d | d | d |

| X60 | 0.26 e | 1.40 e | 0.03 | 0.03 | f | f | f |

| X65 | 0.26 e | 1.45 e | 0.03 | 0.03 | f | f | f |

| X70 | 0.26e | 1.65 e | 0.03 | 0.03 | f | f | f |

| a. Cu ≤ = 0.50% Ni; ≤ 0.50%; Cr ≤ 0.50%; na Mo ≤ 0.15%, | |||||||

| b. Maka mbelata ọ bụla nke 0.01% n'okpuru oke mkpokọta carbon akọwapụtara, mmụba nke 0.05% karịa oke mkpokọta akọwapụtara maka Mn ka akwadoro, ruo oke kachasị nke 1.65% maka ọkwa ≥ L245 ma ọ bụ B, mana ≤ L360 ma ọ bụ X52; ruo oke kachasị nke 1.75% maka ọkwa > L360 ma ọ bụ X52, mana < L485 ma ọ bụ X70; na ruo oke kachasị nke 2.00% maka ọkwa L485 ma ọ bụ X70., | |||||||

| c. Ọ gwụla ma ekwenyere na NB + V ≤ 0.06%, | |||||||

| d. Nb + V + TI ≤ 0.15%, | |||||||

| e. Ọ gwụla ma ekwenyere ihe ọzọ., | |||||||

| f. Ọ gwụla ma ekwenyere ihe ọzọ, NB + V = Ti ≤ 0.15%, | |||||||

| g. A naghị ekwe ka etinye B n'amamihe, a naghịkwa ekwe ka ihe fọdụrụ B ≤ 0.001% | |||||||

| Ngwakọta kemịkalụ maka ọkpọkọ PSL 2 nwere t ≤ 0.984” | |||||||||||||||||||||

| Ọkwa ígwè | Nkebi oke, pasentị dabere na nyocha okpomọkụ na ngwaahịa | Ngwakọta Carbon | |||||||||||||||||||

| C | Si | Mn | P | S | V | Nb | Ti | Ndị ọzọ | CE IIW | CE Pcm | |||||||||||

| kacha b | kachasị | kacha b | kachasị | kachasị | kachasị | kachasị | kachasị | kachasị | kachasị | ||||||||||||

| Pipe Enweghị Nsogbu na Njikọta | |||||||||||||||||||||

| BR | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42R | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| BN | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | c | c | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42N | 0.24 | 0.4 | 1.2 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46N | 0.24 | 0.4 | 1.4 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X52N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.1 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X56N | 0.24 | 0.45 | 1.4 | 0.025 | 0.015 | 0.10f | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||||

| X60N | 0.24f | 0.45f | 1.40f | 0.025 | 0.015 | 0.10f | 0.05f | 0.04f | g,h,l | Dịka ekwekọrịtara | |||||||||||

| BQ | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52Q | 0.18 | 0.45 | 1.5 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X56Q | 0.18 | 0.45f | 1.5 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X60Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65Q | 0.18f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70Q | 0.18f | 0.45f | 1.80f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80Q | 0.18f | 0.45f | 1.90f | 0.025 | 0.015 | g | g | g | m,j | Dịka ekwekọrịtara | |||||||||||

| X90Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | Dịka ekwekọrịtara | |||||||||||

| X100Q | 0.16f | 0.45f | 1.9 | 0.02 | 0.01 | g | g | g | j,k | Dịka ekwekọrịtara | |||||||||||

| Pipe a na-agbakọta | |||||||||||||||||||||

| BM | 0.22 | 0.45 | 1.2 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X42M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X46M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||||

| X52M | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| X56M | 0.22 | 0.45f | 1.4 | 0.025 | 0.015 | d | d | d | e,l | 0.43 | 0.25 | ||||||||||

| X60M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X65M | 0.12f | 0.45f | 1.60f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X70M | 0.12f | 0.45f | 1.70f | 0.025 | 0.015 | g | g | g | h,l | 0.43 | 0.25 | ||||||||||

| X80M | 0.12f | 0.45f | 1.85f | 0.025 | 0.015 | g | g | g | m,j | .043f | 0.25 | ||||||||||

| X90M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | m,j | – | 0.25 | ||||||||||

| X100M | 0.1 | 0.55f | 2.10f | 0.02 | 0.01 | g | g | g | m,j | – | 0.25 | ||||||||||

| a. SMLS t>0.787”, oke CE ga-adị ka ekwenyero. Oke CEIIW etinyere fi C > 0.12% yana oke CEPcm ga-adị ma ọ bụrụ na C ≤ 0.12%, | |||||||||||||||||||||

| b. Maka mbelata ọ bụla nke 0.01% n'okpuru oke kachasị akọwapụtara maka C, a na-anabata mmụba nke 0.05% karịa oke kachasị akọwapụtara maka Mn, ruo oke kachasị nke 1.65% maka akara ≥ L245 ma ọ bụ B, mana ≤ L360 ma ọ bụ X52; ruo oke kachasị nke 1.75% maka akara > L360 ma ọ bụ X52, mana < L485 ma ọ bụ X70; ruo oke kachasị nke 2.00% maka akara ≥ L485 ma ọ bụ X70, mana ≤ L555 ma ọ bụ X80; na ruo oke kachasị nke 2.20% maka akara > L555 ma ọ bụ X80., | |||||||||||||||||||||

| c. Ọ gwụla ma ekwenyere ihe ọzọ Nb = V ≤ 0.06%, | |||||||||||||||||||||

| d. Nb = V = Ti ≤ 0.15%, | |||||||||||||||||||||

| e. Ọ gwụla ma ekwetaghị, Cu ≤ 0.50%; Ni ≤ 0.30% Cr ≤ 0.30% na Mo ≤ 0.15%, | |||||||||||||||||||||

| f. Ọ gwụla ma ekwenyere ihe ọzọ, | |||||||||||||||||||||

| g. Ọ gwụla ma ekwenyere ihe ọzọ, Nb + V + Ti ≤ 0.15%, | |||||||||||||||||||||

| h. Ọ gwụla ma ekwenyeghị n'ụzọ ọzọ, Cu ≤ 0.50% Ni ≤ 0.50% Cr ≤ 0.50% na MO ≤ 0.50%, | |||||||||||||||||||||

| i. Ọ gwụla ma ekwenyeghị n'ụzọ ọzọ, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.50% na MO ≤ 0.50%, | |||||||||||||||||||||

| j. B ≤ 0.004%, | |||||||||||||||||||||

| k. Ọ gwụla ma ekwenyeghị n'ụzọ ọzọ, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.55% na MO ≤ 0.80%, | |||||||||||||||||||||

| l. Maka akara paịpụ PSL 2 niile ewezuga akara ndị nwere ihe odide ala ala j kwuru, ihe ndị a na-emetụta. Ọ gwụla ma ekwenyere na ọ bụghị ihe ọzọ, a naghị ekwe ka etinye B n'uche na ihe fọdụrụ B ≤ 0.001%. | |||||||||||||||||||||

| PSL | Ọnọdụ Nnyefe | Ọkwa ọkpọkọ |

| PSL1 | A na-akpụgharị ya, a na-ahazi ya nke ọma, a na-ahazikwa ya nke ọma | A |

| A na-agbanwe agbanwe dịka a na-akpọgharị, a ... | B | |

| A na-agbanwe agbanwe, na-eme ka a na-agbanwe agbanwe, ...eme ka ọ dị mma. | X42, X46, X52, X56, X60, X65, na X70 | |

| PSL 2 | A na-akpọgharị dịka a na-akpọgharị | BR, X42R |

| Nhazi nke a na-akpọ "normalizing", "normalizing", "normalizing" ma ọ bụ "normalized" ma "debere" | BN, X42N, X46N, X52N, X56N, X60N | |

| Emechiri ma mee ka obi dajụọ | BQ, X42Q, X46Q, X56Q, X60Q, X65Q, X70Q, X80Q, X90Q, X100Q | |

| Akpụpụtara thermomechanical ma ọ bụ thermomechanical site na thermomechanical | BM, X42M, X46M, X56M, X60M, X65M, X70M, X80M | |

| A na-akpọgharị Thermomechanical | X90M, X100M, X120M | |

| Oke (R, N, Q ma ọ bụ M) maka ọkwa PSL2, bụ nke ọkwa ígwè |

PSL bụ mkpụmkpụ maka Ọkwa Nkọwapụta Ngwaahịa ma mejupụtara PSL1 na PSL2. Ọ dị ka ọkwa mma.

PSL1 na PSL2 adịghị iche na nnwale ahụ, kamakwa ihe mejupụtara kemịkalụ na ihe ndị mejupụtara ya.

PSL2 siri ike karịa PSL1 gbasara ihe mejupụtara kemịkalụ, ihe ndị na-eme ka ọ dị ike, ule mmetụta, nnwale na-anaghị emebi emebi, na ihe ndị ọzọ.

Nnwale Mmetụta

Nnwale mmetụta - Achọghị maka PSL1, mana ọ bụ maka PSL2 (ma e wezụga X80).

Nnwale Na-anaghị Ebibi Ebibi

PSL1 anaghị achọ nnwale na-anaghị emebi emebi mana PSL2 chọrọ ya.

(Nnwale na-anaghị ebibi ihe: Nnwale na nnwale na-anaghị ebibi ihe na ọkọlọtọ API 5L na-eji usoro redio, ultrasonic, ma ọ bụ ụzọ ndị ọzọ (na-ebibighị ihe ahụ) iji chọpụta ntụpọ na ezughị okè na pipelines.)

Nkwakọ ngwaahịa bụgba ọtọ n'ozuzu, njikọ waya ígwè, nke ukwuusiri ike.

Ọ bụrụ na ị nwere ihe pụrụ iche achọrọ, ị nwere ike ijinkwakọ ngwaahịa nchara na-egosi, ma mara mma karịa.

Ihe ndị a ga-eme iji chekwaa ma bufee paịpụ ígwè carbon.

1.API 5L Steel Pipea ga-echebe ya pụọ na mmebi nke ihe mberede, mkpụpụ na mbelata kpatara n'oge njem, nchekwa na ojiji.

2. Mgbe ị na-eji paịpụ ígwè carbon, ị kwesịrị ịgbaso usoro nchekwa ndị kwekọrọ na ya ma lezie anya iji gbochie mgbawa, ọkụ, nsí na ihe mberede ndị ọzọ.

3. N'oge eji ya,Pipe ígwè API 5Lkwesịrị izere ịkpọtụrụ okpomọkụ dị elu, ihe ndị na-emebi emebi, wdg. Ọ bụrụ na ejiri ya na gburugburu ebe ndị a, a ga-ahọrọ ọkpọkọ ígwè carbon nke e ji ihe pụrụ iche dịka iguzogide okpomọkụ dị elu na iguzogide nchara.

4. Mgbe ị na-ahọrọ ọkpọkọ ígwè carbon, a ga-ahọrọ ọkpọkọ ígwè carbon nke ihe kwesịrị ekwesị na nkọwapụta dabere na ihe ndị zuru oke dịka gburugburu ebe a na-eji ya, ihe ndị dị n'etiti, nrụgide, okpomọkụ na ihe ndị ọzọ.

5. Tupu e jiri paịpụ ígwè carbon mee ihe, a ga-eme nyocha na ule dị mkpa iji hụ na àgwà ha ruru ihe achọrọ.

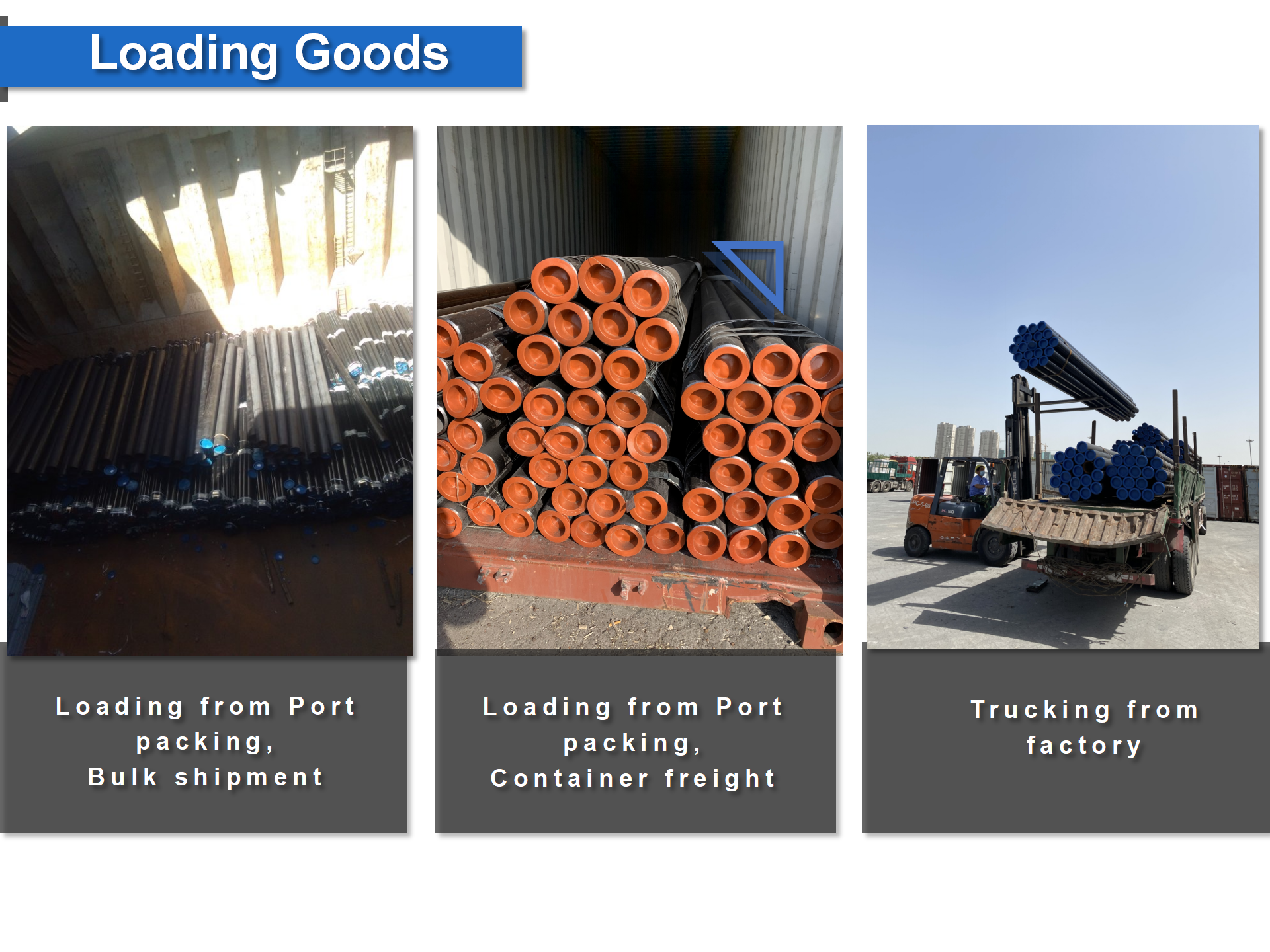

Njem:Nnyefe Ngwa Ngwa (Nnyefe Ihe Nlereanya), Ikuku, Ụgbọ okporo ígwè, Ala, Mbupu n'oké osimiri (FCL ma ọ bụ LCL ma ọ bụ Nnukwu)

Q: Ị bụ onye nrụpụta?

A: Ee, anyị bụ ndị nrụpụta ígwè na-agba gburugburu nke dị na obodo Daqiuzhuang, obodo Tianjin, China

Q: Enwere m ike ịnweta iwu nnwale naanị tọn ole na ole?

A: N'ezie. Anyị nwere ike ibuga ibu ahụ maka gị site na ọrụ LCL. (Ọ dịghị ibu ibu dị obere)

Q: Ọ bụrụ na sample bụ n'efu?

A: N'efu ihe nlele, mana onye zụrụ ya na-akwụ ụgwọ maka ibu ahụ.

Q: Ị bụ onye na-eweta ọlaedo ma na-eme nkwa azụmaahịa?

A: Anyị na-enye ndị na-ere ahịa ọlaedo afọ iri na atọ ma na-anabata nkwa azụmaahịa.